Military manufacturing runs on precision. CNC machining delivers it.

That’s not marketing. That’s just how modern defense production works. The precision, strength, and reliability that mission-critical equipment demands? CNC is how you get there.

No room for error here. None. A failed part in the field can cost lives.

What You Need to Know

| Category | Details |

| Typical Component Lifespan | 10–30+ years depending on material, stress load, and environment |

| Common Materials | Titanium, hardened steels (4140/4340), aerospace aluminum (6061/7075), composite materials |

| Cost Range | Simple parts: $50–$300 each / Complex multi-axis parts: $500–$5,000+ |

| Production Speed | Prototypes in days / Short-run production in 1–3 weeks |

| Key Industries Served | Defense contractors, aerospace programs, vehicle and weapons manufacturers, R&D labs |

| Local Insight (USA) | Growing demand for high-tolerance components and secure domestic production to reduce overseas reliance |

Why Defense Manufacturing Needs CNC

Military parts work under extreme heat. Pressure. Vibration. Impact. Conditions that would destroy commercial-grade components.

Even a tiny error can affect performance. Or worse. Put lives at risk.

CNC machining handles these challenges. Unmatched precision. Repeatable results. Every single time.

Accuracy That Actually Matters

Modern CNC equipment uses digital controls to carve metal with tolerances measured in microns. Not millimeters. Microns. That’s the level we’re talking about.

Why does that matter? These tolerances are vital for firearm receivers and trigger assemblies. Missile and drone guidance housings. Avionics brackets for jets and helicopters. Radar and optical sensor shells. Mechanical parts for armored vehicles.

CNC machines repeat the same movement thousands of times. Near-perfect consistency. Every part fits. Every part functions. Every part performs exactly as intended.

Failure rates in the field drop dramatically. When lives depend on equipment working right, that’s not a nice-to-have. It’s everything.

Materials That Survive Combat

Defense parts face abuse far beyond commercial applications. Way beyond. CNC machining works with materials chosen specifically for strength, heat resistance, and corrosion protection.

Titanium. Lightweight. Extremely strong. Corrosion-proof. Expensive but worth it for the right applications.

4140/4340 hardened steel. Ideal for barrels, receivers, and impact-loaded parts. Takes a beating and keeps working.

Aerospace aluminum (6061, 7075). High strength-to-weight ratio. Common in aircraft and vehicle components.

Composites. Used in lightweight or stealth-related applications. Specialized but increasingly important.

CNC machining shapes these materials with precision. Maintains structural integrity throughout the process. Result? Longer equipment life. Fewer maintenance intervals. Dependable performance when conditions get ugly.

Prototyping That Keeps Up With Modern Warfare

Defense projects evolve quickly. Requirements shift. Timelines compress. Nobody has months to wait around for tooling anymore.

CNC machining supports rapid prototyping. Engineers turn digital CAD files into physical prototypes within days. Test form, fit, and function immediately. Modify designs based on feedback. Transition into production without changing processes.

This speed matters. Technology changes fast. Field requirements shift in real time. Prototyping that takes months? That’s a competitive disadvantage now.

Security You Can Actually Control

Defense components require security. Obviously. This isn’t controversial.

CNC machining allows in-house production. Reduces exposure to overseas suppliers. Controlled digital workflows keep sensitive data protected. Traceable material certifications for compliance. Restricted access protocols around proprietary designs.

Critical components stay confidential. Federal security standards get met. No compromises on either front.

Complex Parts Without Complex Problems

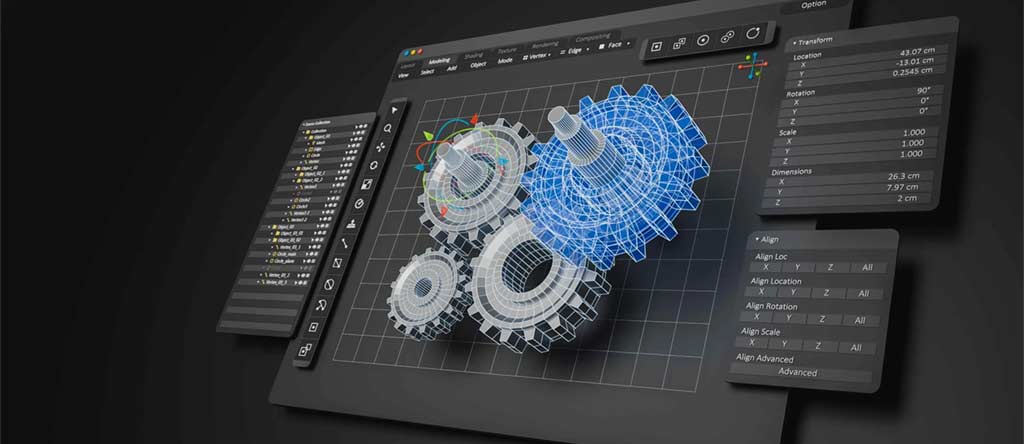

Military equipment is more advanced than ever. Aerodynamic surfaces. Internal cooling channels. Geometries that would’ve been impossible a decade ago.

Multi-axis CNC machining—especially 5-axis mills—makes these shapes possible.

Lightweight structures with internal pockets. High-precision housings for optics and sensors. Intricate thermal management features. Multi-surface parts that must align perfectly. Tight-fitting assemblies for drones and missiles.

Designers can push boundaries now. Manufacturability isn’t the bottleneck anymore. If you can design it, CNC can probably cut it.

How CNC Stacks Up Against Other Methods

| Method | Strengths | Limitations | Best Use |

| CNC Machining | Highest precision, strong materials, excellent repeatability | Cost increases for mass production | Defense-grade metal parts |

| 3D Printing/Additive | Great for complex shapes, fast prototyping | Limited material strength | Lightweight housings, non-load parts |

| Casting | Good for high-volume production | Less accurate, slower changes | Larger metal components |

| Sheet Metal Fabrication | Fast and affordable | Not ideal for complex 3D parts | Enclosures, brackets, shields |

For military applications requiring durability and precision? CNC machining. Gold standard. Nothing else comes close for critical components.

What Drives Defense Machining Costs

Material Type

Titanium and hardened steels increase machining time. Tool wear goes up. Costs follow. No way around it.

Part Complexity

Multi-axis machining, deep pockets, internal channels. Longer run times. More complex means more expensive. Always.

Tolerance Requirements

Micron-level tolerances need slower cutting speeds. More measurements. More time. Precision costs money.

Production Volume

Small runs cost more per unit. Larger runs allow repeat setups and tooling efficiency. Basic economics.

Certification & Quality Standards

Defense manufacturing requires documentation. Testing. Quality protocols. Adds overhead. But it’s worth it. Actually, it’s mandatory.

Finishing Requirements

Anodizing, passivation, coatings, heat treatment. Adds cost and lead time. Sometimes necessary. Sometimes optional. Depends on the application.

How Defense CNC Projects Work

1. Define Requirements

Materials. Tolerances. Quantities. Environmental conditions. Get specific upfront. Saves headaches later.

2. Submit CAD Files

Engineers review for manufacturability. Catch issues before they become expensive.

3. DFM Feedback

Suggestions to improve part strength. Reduce cost. Simplify machining. Take this feedback seriously.

4. Prototype Production

CNC machines cut test pieces. Immediate evaluation. Fast turnaround.

5. Testing & Validation

Environmental testing. Structural testing. Functional testing. Verify everything works before committing to production.

6. Production Launch

Finalized components enter short-run or full-scale machining. This is where it gets real.

7. Inspection & Documentation

Dimensional reports. Certifications. Traceability. Everything documented. Defense contracts require it.

What’s Happening in U.S. Defense CNC Right Now

Titanium demand is up. Modern aircraft and missiles need it. Drone and autonomous system machining is growing fast. Components are getting smaller and more precise. Security requirements for digital CAD and CAM workflows are tightening. More production is moving back to U.S. soil.

Overseas dependence is a vulnerability. Industry knows it now. Domestic capability matters.

FAQs

What makes CNC machining ideal for military applications?

Precision. Repeatability. Strong materials. Mission-critical components where failure isn’t an option. CNC delivers on all of it.

What materials are commonly used in defense machining?

Titanium. Hardened steels. Aerospace aluminum. Composites. Depends on the application and stress requirements.

How accurate are CNC-machined defense parts?

Tolerances within ±0.0005” or tighter. Micron-level precision is routine. Not exceptional. Routine.

Can CNC machining handle classified or sensitive projects?

Yes. Secure in-house workflows protect intellectual property. Controlled access. Protected data. That’s the whole point.

Is CNC machining cost-effective for small production runs?

Yes. No molds. No tooling. Setup once and run what you need. CNC excels at short runs.

Why Defense Manufacturers Work With Styner Machine Tools

Styner Machine Tools serves U.S. defense with high-tolerance CNC machining. Rapid prototyping. CAD-to-production support. We understand security requirements. Accuracy requirements. Documentation requirements.

Short-run prototypes. Precision milling. Complex multi-axis work. American manufacturing. Real experience.

Parts that perform when it matters most.