Want to know how CNC machining actually works? Here is the breakdown.

CNC is the backbone of modern manufacturing. Not an overstatement. Precise parts. Consistent quality. Complex shapes that would take forever by hand.

Prototyping to full production—CNC handles it all. Raw materials go in, finished components come out. Accuracy that manual methods just cannot match.

So how does a chunk of metal become a critical machine part? Let me walk you through it.

Snapshot: CNC Machining

| Feature | The Reality |

| Equipment Lifespan | 10-20 years if maintained right |

| Cost per Part | $5-$500+ based on size and complexity |

| Materials | Aluminum, steel, titanium, plastics, composites |

| U.S. Trends | Fast prototypes and precision parts—demand is up |

| Production Range | One-offs to thousands of units |

| Quality | Dimensions and finishes stay consistent |

CNC vs. Other Methods

Why pick CNC over 3D printing or manual milling? Fair question.

CNC vs. Manual Machining

Manual work depends on who is running the machine. Their skill. Their attention. CNC automates the whole thing. Same precision across hundreds or thousands of parts. No variability.

CNC vs. 3D Printing

3D printing is great for plastic prototypes and weird geometries. But metals? Tight tolerances? CNC wins on strength, finish, and dimensional accuracy. Not even close.

CNC vs. Laser or Waterjet

Cutting methods shape material fast but that is about it. CNC drills, mills, turns, and engraves. All in one setup. Way more versatile.

CNC hits the sweet spot. Versatility. Precision. Durability. That is why shops still rely on it.

What Drives Performance and Cost

Not every CNC job is the same. A few things affect what you pay and what you get.

1. Material Type

Titanium and stainless steel are tough to cut. Slower speeds. Special tools. Production time goes up. So does the bill.

2. Part Complexity

Multi-axis features and intricate shapes mean more programming. More machine time. More cost.

3. Tooling Quality

Good cutting tools last longer and cut cleaner. Cheap tools dull fast and leave rough finishes. You get what you pay for.

4. Machine Capabilities

Multi-axis CNC handles complex shapes better than basic setups. Fewer operations. Less time. Lower cost in the end.

5. Production Volume

Bigger runs mean lower cost per part. Setup gets spread across more pieces.

The Process: Step by Step

Step 1: Design and Programming

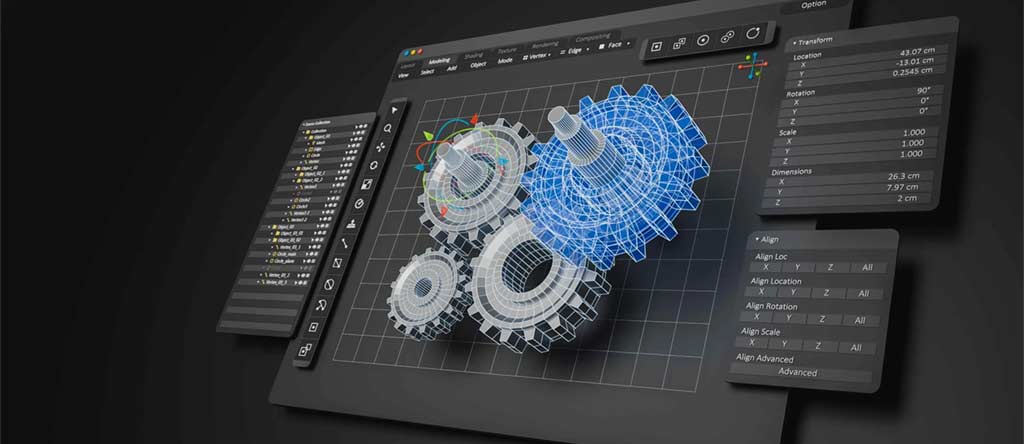

Everything starts with a digital design. CAD software. You define dimensions, geometry, tolerances. That file is your blueprint.

Then CAD goes into CAM software. Converts the design into G-code. That is what CNC machines actually read. Which tools to use. How fast to move. How deep to cut. All spelled out.

Good programming matters here. Efficient G-code means less waste, less tool wear, smoother operation. Bad programming causes headaches.

Step 2: Setup and Machining

Program done? Now prep the machine.

Clamp the raw material down. Load the right tools—cutters, drills, mills. Calibrate the zero point so the machine knows where everything starts.

Then it runs. Milling shapes surfaces and cuts slots. Turning spins the workpiece for cylindrical parts. Drilling makes holes. Laser or waterjet marks and cuts where needed.

Multi-axis machines move multiple directions at once. Complex shapes happen in a single setup. The machine follows instructions exactly. Every time.

Step 3: Inspection and Finishing

Machining done? Parts get checked.

Calipers. Micrometers. CMMs. Dimensions and tolerances verified. Then finishing—deburring sharp edges, polishing surfaces, coating for corrosion resistance, heat treating for durability.

Aerospace, automotive, medical—those industries do not accept sloppy work. Parts that pass go to assembly or shipment. Parts that fail get scrapped or reworked.

U.S. Trends

CNC keeps evolving. Here is what is happening in American shops right now.

- Multi-axis machines getting more common. Complex parts done faster.

- Short runs and rapid prototyping growing. Companies want to iterate quick.

- Smart manufacturing expanding. IoT sensors and real-time monitoring catch problems early. Less downtime.

FAQs

What materials work with CNC?

Metals, plastics, composites, specialty alloys. Pretty much anything you need to shape precisely.

How long does machining take?

Minutes to hours. Depends on the part, the material, and the setup involved.

Is CNC better than 3D printing?

For metals and precision work? Yes. Stronger parts. Tighter tolerances. Better finishes.

How do shops ensure quality?

Inspection tools like CMMs, micrometers, calipers. Plus finishing processes where needed.

Can CNC handle small runs?

Yep. Prototypes and low-volume jobs work great. Modern CNC is flexible that way.

What industries use CNC most?

Aerospace, automotive, medical, electronics, robotics. Anywhere precision actually matters.

Why Styner Machine Tools

Styner Machine Tools has been turning ideas into precise components for manufacturers across the USA.

Experienced team. Advanced equipment. Every part meets spec.

One prototype or a full production run—we deliver. Precision manufacturing. Quality that holds. That is Styner.