Had coffee last month with a product designer named Christine. Works for a medical device company out of Minneapolis. She’d just spent three frustrating weeks going back and forth with her manufacturing team about how to produce a new surgical instrument housing.

“Half the team wanted to 3D print it,” she said. “The other half insisted on CNC. Everyone had strong opinions. Nobody had the same data.”

This argument happens constantly. CNC milling versus additive manufacturing—which is better? The honest answer is frustrating: it depends. Depends on what you’re making, what material you need, how many you need, and what tolerances matter.

But here’s the thing. Once you understand what each process actually does well—and where each one struggles—the decision usually becomes obvious. Christine’s team eventually figured it out. The housing needed tight tolerances on mating surfaces but had some internal channels that would be brutal to machine. They printed the rough shape, then CNC-finished the critical features.

Hybrid approach. Best of both worlds. That’s increasingly where smart manufacturing ends up. Not either/or, but and.

Let me walk you through how to think about this decision.

Quick Comparison: CNC Milling vs. Additive

| Category | CNC Milling | Additive Manufacturing |

| Part Lifespan | Excellent for functional, load-bearing parts | Varies—polymers shorter, metals comparable with post-processing |

| Cost Range (USA) | $75–$2,000+ per part | $25–$800+ per part |

| Best For | Precision, strength, production runs | Complex shapes, fast prototypes, lightweight structures |

| Material Options | Very broad—metals, plastics, composites | Moderate—polymers, resins, some metals |

| Waste Level | Higher—subtractive process creates chips | Minimal—uses only what’s needed |

| Speed | Fast for mid-to-high volume | Fast for prototypes, slower for large builds |

The Case for CNC Milling

Talked to a manufacturing engineer named Derek at an aerospace supplier last year. Guy’s been doing this work for about twenty years. I asked him why his shop still runs mostly CNC when everyone’s talking about 3D printing.

He laughed. “People ask me that all the time. I show them the tolerance specs on our parts. Then I show them what a 3D printer actually achieves. Conversation usually ends there.”

That’s the core advantage of CNC milling. Precision. A good CNC shop holds tolerances from ±0.001″ to ±0.005″ routinely. Surface finishes come off the machine ready for assembly—no secondary operations needed in many cases. Parts cut from solid stock have uniform material properties throughout, which matters enormously for load-bearing applications.

Material Versatility

CNC machines cut almost anything rigid. Aluminum, steel, stainless, titanium. Engineering plastics like Delrin, ABS, Nylon, PEEK. Composites. Exotic alloys for aerospace and defense applications. If you can clamp it and it doesn’t melt under cutting heat, you can probably mill it. That range of material options is hard to match with any other single process.

That matters when your application demands specific material properties—heat resistance, chemical compatibility, mechanical strength, fatigue resistance. CNC doesn’t limit your material choices the way additive often does. You pick the material the application needs, not the material the printer can handle.

Production Speed at Scale

Here’s where CNC really shines. Once a job is programmed and fixtured, the machine runs. Part after part, consistent quality, minimal operator intervention. Need fifty brackets by Friday? A hundred? A thousand? CNC scales in ways additive simply can’t match for most applications.

Additive manufacturing struggles with volume. Printing takes time—layer by layer, hour by hour. For one part, that’s fine. For ten parts, maybe. For production quantities, the math stops working. Print times don’t scale the way machining time does.

Where CNC Struggles

CNC isn’t perfect. It’s subtractive—you’re removing material, which means waste. For expensive metals like titanium or Inconel, those chips add up fast. Some shops recycle, but you’re still paying for material that ends up in the scrap bin instead of your finished part.

Geometry constraints are the bigger issue. Cutting tools have to physically reach surfaces. Internal cavities, lattice structures, organic shapes with undercuts—these are difficult or impossible to machine. The tool has to get there, and sometimes there’s simply no path that works. That’s where additive shines.

The Case for Additive Manufacturing

Met a design engineer named Paul at a trade show couple years back. Works in aerospace, specifically on lightweight structural components. He’s one of the true believers in additive.

“I can design parts that would be physically impossible to machine,” he told me. “Internal cooling channels that follow the exact path they need to follow. Lattice structures that cut weight by 60% without losing strength. Stuff that used to be science fiction.”

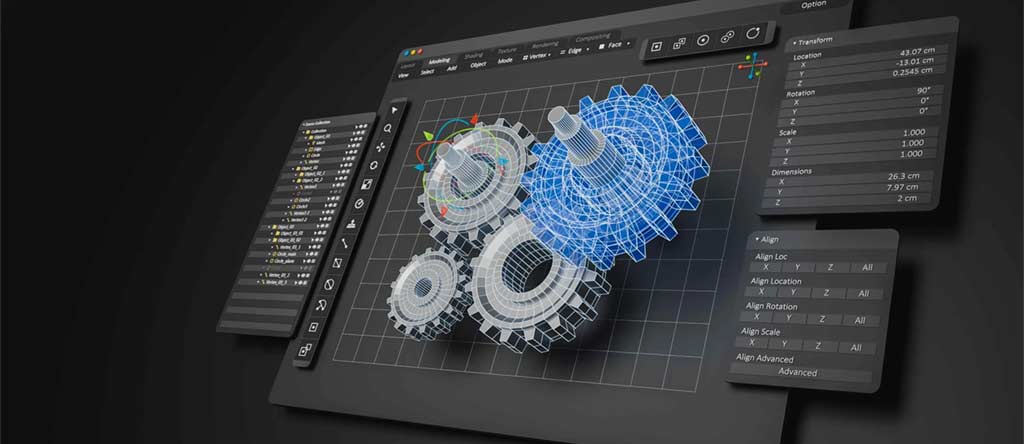

He’s not wrong. Additive manufacturing builds parts layer by layer, which means the tool access constraints that limit CNC simply don’t apply. If you can model it in CAD software, you can probably print it. That freedom opens design possibilities that traditional manufacturing simply can’t touch.

Design Freedom

The shapes additive enables are genuinely remarkable:

- Internal channels that snake through solid parts—impossible to drill, easy to print

- Lattice and honeycomb structures that provide strength with minimal weight

- Organic shapes optimized by software for stress distribution

- Custom one-offs that would cost a fortune to tool up for traditional manufacturing

For aerospace brackets, medical implants, custom jigs, and lightweight prototypes, this design freedom changes what’s possible. Engineers can optimize for performance rather than manufacturability constraints.

Waste and Prototyping Economics

Additive only uses the material that ends up in the part (plus support structures, which are usually minimal compared to machining waste). No chips filling the scrap bin. No cutting fluid to dispose of. For expensive materials, that efficiency matters a lot. Every ounce of titanium or Inconel that ends up in the part instead of the recycling bin is money saved.

Prototyping is where additive really wins economically. Need to test five design variations? Print all five overnight. Iterate based on what you learn. No tooling costs, no setup time, no minimum order quantities standing between you and physical parts. The speed from CAD file to something you can hold in your hands is genuinely transformative for development cycles. I’ve seen teams compress months of iteration into weeks.

Where Additive Struggles

Paul’s honest about the limitations too. “Surface finish out of the printer isn’t great,” he admits. “Most of my parts go to CNC for finishing critical surfaces. And material properties aren’t quite as good as wrought stock—yet.”

That’s the reality. Printed parts often need secondary operations—sanding, machining, polishing—to reach production-grade finishes. Material strength, especially in polymers, doesn’t match what you get from solid stock. Layer adhesion can create weak points. And for large parts, print times stretch into days, which kills throughput for volume production.

A Simple Framework for Deciding

When Christine’s team finally stopped arguing and started analyzing, they used something like this framework:

- What’s the part actually doing? – Load-bearing production part? Probably CNC. Quick prototype to test a concept? Probably additive. Functional prototype that needs real material properties? Could go either way.

- What material does it need? – If you need specific metal alloys for strength or heat resistance, CNC likely wins. If standard polymers or select printable metals work, additive is an option.

- How complex is the geometry? – Organic shapes, internal channels, lattice structures push toward additive. Simple prismatic shapes with accessible features are CNC territory.

- How tight are the tolerances? – ±0.001″ to ±0.005″? CNC. ±0.010″ or looser? Additive might work. Critical mating surfaces? CNC those features even if you print the rest.

- How many do you need? – One to ten parts: additive often makes sense. Fifty or more: CNC usually wins on economics and consistency. Somewhere in between: run the numbers both ways.

And don’t forget the hybrid option. Print the complex shape, machine the critical features. Increasingly, that’s the smart play for parts that need both geometric complexity and tight tolerances in specific areas.

What Actually Affects the Price Tag

Understanding cost drivers helps you estimate budgets before you’re too deep in the design process. Getting this wrong means unpleasant surprises later.

CNC Milling Price Drivers

- Material choice – Titanium costs more than aluminum. Harder materials take longer to cut and chew through tooling faster.

- Part complexity – More operations, more setups, more time. Complex parts cost more than simple ones.

- Tolerance requirements – Tighter tolerances require slower cuts and more inspection. Precision costs.

- Volume – Setup costs spread across more parts at higher volumes. Per-piece price drops.

- Surface finishing – Polishing, coating, anodizing add time and expense.

Additive Manufacturing Price Drivers

- Layer resolution – Finer layers look better but take exponentially longer. Time is money.

- Print material – Metal printing costs more than polymer. Specialty materials cost more than standard.

- Build volume – Larger parts take longer. Multiple parts per build can improve economics.

- Post-processing – Support removal, surface finishing, machining critical features. Often overlooked in initial quotes.

A shop owner I know—guy named Rich who’s been in manufacturing for 35 years—tells customers to budget 20-30% extra for post-processing on printed parts. “People see the print price and think that’s the whole story,” he says. “It’s not. Support removal, surface finishing, machining critical features—it all adds up. Factor that in from the start.”

Related Processes Worth Knowing About

CNC milling and additive aren’t the only options. Depending on your application, these might fit better or complement either process. Worth knowing they exist:

- CNC turning – Better than milling for round, cylindrical, or shaft-style parts. If your part spins on a lathe, turning is probably faster and cheaper.

- Waterjet and laser cutting – Great for flat profiles. Cut blanks before machining or use as finished 2D parts.

- Plasma cutting – Handles thick metal plates. Lower precision than laser but faster and cheaper for heavy stock.

- Wire EDM – For extremely tight tolerances in hard materials. Slower and more expensive but achieves precision CNC can’t match on certain features.

Where Manufacturing Is Heading

Been watching this space closely. Few patterns worth noting:

- Hybrid workflows becoming standard – Print rough, machine finish. Best of both worlds. The lines between processes are blurring.

- Lattice structures spreading – Aerospace led, but automotive and consumer products are catching up. Lightweight and strong sells.

- Metal additive maturing – Used to be exotic. Now it’s practical for tooling inserts, aerospace components, medical implants. Still expensive but getting better.

- Faster iteration expected – EV development and consumer product cycles demand speed. Prototyping timelines compressed dramatically.

- Software getting smarter – AI-enhanced CAM reduces CNC programming time. Generative design tools optimize parts for additive. The tools keep improving.

The shops thriving are the ones that understand both processes and know when to use each. Dogmatic attachment to one approach leaves money and capability on the table. The future belongs to manufacturers who can pick the right tool for each job—and combine tools when that makes sense.

FAQs

1. Which makes stronger parts—CNC or 3D printing?

CNC-milled parts are generally stronger because they’re cut from solid material with uniform properties throughout. Printed parts can have layer adhesion issues and anisotropic properties—stronger in some directions than others. Metal printing is closing the gap, but wrought stock still wins on pure strength. For structural, load-bearing applications, CNC is usually the safer bet.

2. Is 3D printing actually cheaper?

For prototypes and complex low-volume parts, often yes. For production runs of any real size, usually no. The breakeven point varies by part geometry and material—run the numbers both ways before assuming either answer is right for your situation.

3. Can you CNC-finish a 3D-printed part?

Absolutely. This hybrid approach is increasingly common. Print the complex shape, then machine critical surfaces to final tolerance and finish. Gets you the best of both processes.

4. What materials can’t be 3D printed?

Many high-strength alloys, heat-treated steels, and certain engineering plastics still lack viable printing processes. If your application demands specific material properties, check what’s actually printable before committing to additive.

5. When does the hybrid approach make sense?

When you need complex geometry that’s hard to machine AND tight tolerances on mating surfaces. Print the shape, machine the critical features. Also works when material cost is high—print near-net shape to minimize waste, then finish to spec.

6. Which process is faster?

For a single prototype, additive is usually faster—no programming, no setup, just print. For production volumes, CNC is faster because once it’s running, parts come off quickly. Large or complex prints can take days, while CNC can produce multiple parts per hour.

Why Styner Machine Tools

Styner Machine Tools provides precision CNC milling alongside advanced prototyping support. We help customers figure out which process actually fits their project—not just push one approach because it’s what we prefer.

Need production-ready metal components? We’ve got the CNC capability. Need fast prototypes to test concepts? We can help with that too. Need both—hybrid workflows that combine printing and machining? That’s increasingly the smart play, and we know how to execute it.

The goal is getting you the right parts, the right way, at the right price. Sometimes that’s pure CNC. Sometimes it’s additive. Sometimes it’s both working together. We’ve helped customers navigate this decision hundreds of times—we know what works.

American manufacturing. Real expertise. Solutions that actually fit your specific project needs.

Contact Styner Machine Tools at CNCFAB.SHOP to discuss your project.