Additive manufacturing—most people just call it 3D printing—builds parts layer by layer instead of cutting them from solid blocks. Pair it with CNC machining and suddenly you’ve got options. Complex designs that used to be impossible? Doable now. Less material waste? Yep. Faster prototypes? Absolutely. Traditional machining alone can’t touch some of this stuff.

Snapshot: Additive Manufacturing in the CNC World

| Feature | Details |

| Machine Lifespan | 5–10 years with proper maintenance |

| Cost Range | $5,000 entry-level FDM to $500,000 industrial metal printers |

| Materials | Plastics, resins, metals (aluminum, stainless, titanium), composites |

| USA Trend | Shops combining additive and CNC for faster, cheaper, more customized parts |

Sounds high-tech and complicated? It’s actually pretty practical for modern shops already.

What Additive Manufacturing Really Means for CNC

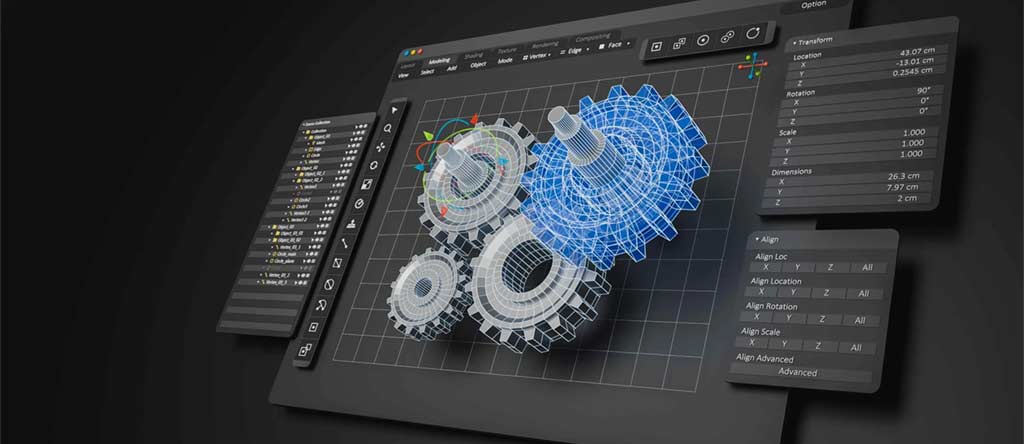

Here’s the basic idea. Additive manufacturing builds material up layer by layer. CNC machining carves material away from a solid block. Small distinction on paper. Massive difference in practice.

Popular additive techniques worth knowing about: FDM (Fused Deposition Modeling) melts plastic filament and stacks it layer by layer. SLA (Stereolithography) cures liquid resin with light to form precise shapes. SLS (Selective Laser Sintering) fuses powdered material with a laser. DMLS (Direct Metal Laser Sintering) builds metal components layer by layer—aerospace and automotive love this one.

From a CNC perspective, additive opens up designs that were previously impossible. Or at least impossibly expensive. Internal channels. Lattice structures. Intricate lightweight components. Also lets engineers iterate on ideas fast. Huge difference when you’re racing to get products to market.

Why CNC Pros Are Excited About Additive Manufacturing

Additive isn’t here to kill CNC. It’s here to make CNC work smarter. Here’s why machinists actually like it.

Complex Designs Made Simple

Need a part with crazy internal channels? Lightweight structures that would take forever to machine? Additive handles it. CNC alone can’t do this stuff efficiently. Not even close.

Way Less Waste

CNC starts with a solid block and cuts away everything that isn’t the part. Additive only uses what’s actually needed. On expensive metals especially, that savings adds up fast.

Faster Prototyping

Testing a design used to mean days or weeks waiting on CNC setups. Additive gets you a prototype in hours. Maybe a couple days for something complicated. Game changer for development cycles.

Creative Freedom

Designers can experiment with organic shapes. Weight optimization. Structural complexity that would be nightmarish to machine traditionally. Opens up possibilities.

Combine additive and CNC and you get intricate, lightweight designs that still hit precise tolerances. Best of both worlds. Not an exaggeration.

Limitations and How CNC and Additive Work Together

No technology is perfect. Additive has real limits.

Surface finish and precision can be rough coming off the printer. Critical surfaces often need CNC finishing. Material options are growing but CNC still offers the widest selection. Some printed parts need post-processing to hit performance requirements.

The Hybrid Approach That Actually Works

Most effective strategy? Combine them.

Start with a CAD design planned for additive building. Pick your method—FDM, SLA, SLS, DMLS depending on materials and complexity. Print a near-net shape. Then CNC-finish the surfaces requiring high precision or smooth finish. Inspect and test to confirm everything meets spec.

This approach cuts waste. Saves time. Lets manufacturers explore design freedom without compromising quality. Win across the board.

Comparing Additive and Subtractive Manufacturing

| Feature | Additive | CNC (Subtractive) |

| Material Waste | Very low | High |

| Design Complexity | Extremely high | Moderate |

| Surface Finish | Moderate | Excellent |

| Production Speed | Fast for prototypes | Slower for complex parts |

| Material Options | Growing | Wide range |

Pretty clear from the comparison. Additive extends what CNC can do. Doesn’t replace it. Hybrid workflows are popular for exactly this reason.

Current Trends and USA Outlook

Hybrid machines are on the rise. Manufacturers embracing setups that combine additive and subtractive in a single workflow. Materials keep improving too. New metal powders and composites mean stronger, more functional parts than ever.

Cost savings are real. Local shops cutting prototyping costs by 30–50%. Huge deal for smaller operations trying to compete. Aerospace, automotive, medical device companies leading the charge. All looking for lighter, stronger, more optimized designs.

Even smaller shops are taking advantage of hybrid workflows now. Staying competitive without sacrificing quality. Not just a big company thing anymore.

FAQs

Can additive manufacturing replace CNC machining?

Not really. Great for complex shapes and fast prototypes. But CNC is still needed for precision surfaces and functional parts. Different tools for different jobs.

Which industries benefit most from hybrid setups?

Aerospace. Automotive. Medical devices. High-performance engineering. Basically anywhere pushing the limits on weight, strength, and complexity.

Are metal parts strong enough straight off the printer?

Many are. Some need post-processing or CNC finishing to hit strict performance requirements. Depends on the application.

How fast can a prototype be ready?

Hours to a few days with additive. Way faster than traditional CNC setups for initial concepts.

What materials work with additive manufacturing?

Plastics. Resins. Metals like aluminum, titanium, stainless steel. New materials getting added constantly. Options keep expanding.

Is hybrid manufacturing worth the investment?

For most shops, yes. Faster development. Less waste. More design possibilities. Numbers usually work out.

Why Styner Machine Tools

Styner Machine Tools has spent decades mastering CNC machining. Now we combine that experience with additive manufacturing to deliver parts that are high-quality, precise, and innovative.

Rapid prototypes. Complex finished components. Our hybrid approach ensures efficiency, quality, and reliability. That’s what Styner brings to the table.