Let’s talk about a problem everyone in product development has faced.

You’ve spent weeks—maybe months—designing a part. It looks perfect on screen. Every dimension checked. Every feature thought through. Then you make the mold, run the first batch, and something’s wrong.

Doesn’t fit. Doesn’t function. Doesn’t assemble the way you expected.

Frustrating? Absolutely. Expensive? Even more so.

That’s why CNC-machined prototype molds exist. You test the design before committing serious money to production tooling. Find problems early. Fix them when changes are cheap.

Here’s how it works and why it matters.

Snapshot

| Factor | What to Expect |

| Prototype mold lifespan | Dozens to hundreds of cycles. Enough for testing. |

| Cost range | $500–$5,000. Depends on complexity and material. |

| Lead time | 1–3 weeks for most molds. Sometimes faster. |

| Common materials | Aluminum, soft steel, machinable plastics |

| Best for | Design validation, fit checks, material testing |

Why Precision Matters for Prototypes

Here’s the thing about injection molding.

The mold determines everything. Wall thickness. Surface finish. Dimensional accuracy. How plastic flows and cools. If the mold is wrong, the part is wrong. Period.

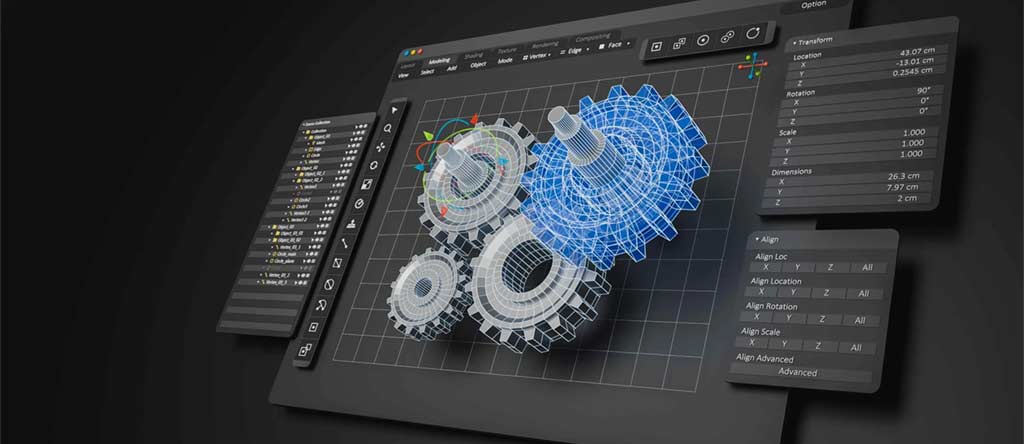

CNC machining translates your CAD models into physical molds with near-perfect accuracy. What you see on screen becomes what you hold in your hands. No guesswork. No hoping the mold maker interpreted your design correctly.

That precision lets you actually test what matters.

Part dimensions and assembly fit. Design flaws you couldn’t see in CAD. Material behavior under real molding conditions.

Thin walls? Intricate threads? Detailed textures? CNC handles it all. You get real-world feedback before investing in production tooling.

That feedback is worth its weight in gold. Trust me.

Speed Changes Everything

Traditional mold-making is slow.

Setting up tools by hand. Tweaking. Running trial cycles. Adjusting. Checking. Adjusting again. It adds up to weeks or months before you have something testable.

I’ve talked to engineers who waited three months for a prototype mold. Three months. In industries where product cycles are measured in quarters, that’s eternity.

CNC machining slashes that timeline.

Your CAD design goes straight to the machine. Program gets generated. Mold gets cut. You have a functional prototype in days instead of weeks.

Why does speed matter so much?

Because in industries like consumer electronics or medical devices, every day counts. Product cycles are short. Competition is fierce. The company that iterates fastest often wins.

With CNC-machined prototypes, you can test, tweak, and retest quickly. Make fast decisions on fit, form, and function. Get to market faster.

That’s not just convenient. That’s competitive advantage. Real competitive advantage.

Cost-Effective Validation

Production molds are expensive.

We’re talking tens of thousands of dollars for hardened steel tooling. Sometimes six figures for complex multi-cavity molds. Makes sense for high-volume production where cost spreads across millions of parts. Doesn’t make sense for testing a design that might change.

I’ve seen companies burn $50,000 on production tooling, only to discover the design needed changes. Then they burned another $50,000 on modified tooling. Painful.

That’s where CNC prototype molds shine.

Aluminum or soft steel instead of hardened tool steel. Cheaper. Faster to machine. Still accurate enough for meaningful testing.

What does that buy you?

You can try multiple iterations without breaking the budget. Test different approaches. Validate fit and function. Check material behavior. Do all of it before committing to expensive production tooling.

Reduce financial risk during development. Gain actionable insights early. Save the big tooling investment for when you’re confident the design is right.

Smart money prototypes first. Every time.

Design Freedom for Complex Parts

CNC machining isn’t limited to simple shapes.

Complex geometries? Done. Undercuts? Handled. Thin walls? No problem. Detailed surface textures? Absolutely.

You’re not constrained by what can be hand-tooled or 3D printed. The same part features you’ll use in production can be prototyped accurately.

Prototype molds also let you experiment with materials.

See how different plastics flow in your specific mold geometry. Watch how they shrink as they cool. Test how finished parts perform under real conditions.

That hands-on testing ensures your final product performs as intended. Fewer surprises during mass production. Fewer costly fixes after tooling is already built.

CNC vs. Other Prototyping Methods

How does CNC stack up against alternatives?

| Method | Accuracy | Speed | Best For |

| CNC Machining | High | Fast | Functional prototypes, complex designs |

| 3D Printing | Moderate | Very Fast | Concept models, visual checks |

| Hand Tooling | Lower | Slow | One-off molds, simple shapes |

CNC hits the sweet spot. Accurate enough for real functional testing. Fast enough to support rapid iteration. Cost-effective enough to try multiple designs.

Industry Applications

CNC prototype molds serve different industries with different needs.

Automotive

Dashboard components. Interior panels. Mechanical assemblies. Prototype molds let engineers validate fit and function before committing to production tooling.

Consumer Electronics

Housings. Connectors. Buttons. In a market where product cycles are measured in months, fast iteration is essential.

Medical Devices

Surgical tools. Diagnostic housings. Implant components. Tight tolerances and strict safety requirements demand accurate prototyping before any production commitment.

The Prototyping Workflow

Here’s how it typically works.

Step 1: Start with a detailed CAD model. The more accurate your design, the better the prototype.

Step 2: Select mold material. Aluminum for most prototypes. Soft steel if you need more cycles.

Step 3: Machine the mold. CNC mills and lathes create the cavity and core.

Step 4: Run test cycles. Mold some parts. Check fit, finish, and material behavior.

Step 5: Iterate as needed. Tweak the design or machining program. Run again.

Step 6: Validate. Confirm the prototype meets specs before greenlighting production tooling.

Follow this process and you catch problems early. Save money. Ship better products.

What Drives Prototype Mold Cost

Several factors affect what you’ll pay.

Mold complexity matters most. More features, tighter tolerances, detailed textures—all add machining time and cost.

Material choice matters. Aluminum is cheaper and faster to machine. Soft steel costs more but handles more cycles.

Part size matters. Bigger molds require more material and more machine time.

Turnaround matters. Rush jobs cost more. Standard timelines save money.

Understanding these factors helps you budget accurately. Helps you make trade-offs. Helps you get the most value from your prototyping investment.

Industry Trends

A few things are shaping prototype mold production.

CAD-to-CNC workflows are getting smoother. Design software talks directly to machining software. Fewer translation errors. Faster turnaround.

Material options keep expanding. High-performance plastics. Biocompatible polymers. Specialty compounds. All of them need precise molds for accurate testing.

Sustainability is driving short-run production. Less material waste during prototyping. More efficient use of resources.

Speed keeps accelerating. What took weeks now takes days. What took days now takes hours in some cases.

CNC prototype molds aren’t just useful—they’re becoming the standard approach for injection molding development.

FAQs

Can CNC prototype molds be used for production?

Usually not. Prototype molds are for low-volume testing. Production molds use hardened steel that lasts hundreds of thousands of cycles.

How long do prototype molds last?

Aluminum or soft steel molds typically handle dozens to hundreds of cycles. Enough for thorough testing, not enough for production.

Is CNC more expensive than 3D printing for prototypes?

Yes, but CNC provides higher precision and actual injection-molded parts. 3D printing works for visual models. CNC works for functional testing.

What materials are used for prototype molds?

Aluminum is most common. Soft steel for higher cycle counts. Machinable plastics for very early-stage testing.

Can CNC handle complex mold designs?

Absolutely. Thin walls, intricate textures, fine details—all achievable with proper programming and tooling.

How fast can I get a prototype mold?

Most small-to-medium molds ship in 1–3 weeks. Rush jobs can be faster depending on complexity and shop capacity.

How many parts can I make with a prototype mold?

Aluminum molds typically handle dozens to a few hundred cycles. Enough for thorough testing and small pilot runs. Not enough for full production.

Do I need production-grade CAD files for prototyping?

Good CAD helps, but even rough models can work for early prototypes. Better files mean better molds, so refine as you go through iterations.

Why Styner Machine Tools

Styner Machine Tools doesn’t just cut molds. We help bring your ideas to life.

Decades of CNC experience. Guidance from design through functional prototype. Precision, speed, and attention to detail.

When you need prototype molds that actually validate your design, Styner delivers.